PRECISION ENGINEERING

There’s a famous line that says: ‘you can’t improve what you don’t measure,’ and today out in Palma, Mallorca at their winter training base, it was the turn of the INEOS Britannia shore team and engineers to run through a re-step of the mast on T6 and thoroughly check and analyse everything ahead of a busy week of testing. The programme is relentless from here on in and the beautifully detailed LEQ12 mast was stepped and re-stepped with laser measuring tools, and traditional plumb lines and theodolites used to make sure perfection, or more like precision, was achieved – nothing is ever ‘perfect’ in the America’s Cup world.

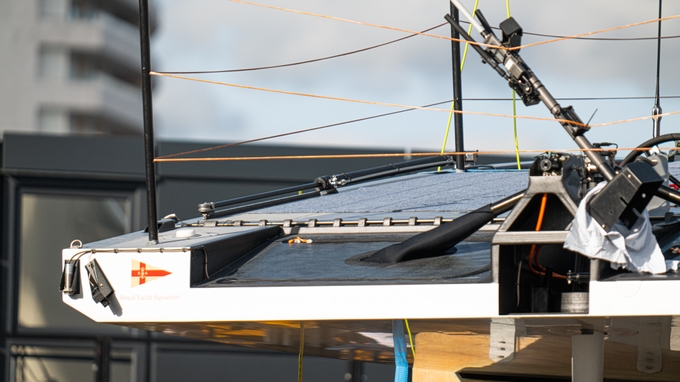

Much attention was paid to the stem junction on the bow with team members using torches to see in and make adjustments from on-deck with help from below and the very-neat connection between the titanium ball connection on the deck that allows for the rotation (perhaps auto-rotation) of the mast and the mast base itself was an area the team spent a lot of time lining up and checking through.

The on-site recon team heard a loud noise early in the afternoon, indicating that load testing was ensuing, and several hydraulic rams could be seen – one for the backstay and two either side on tracks at the aft end of the decks. Plenty of detail could be seen up the rig with what’s assumed to be very neat camera mounts hidden behind carbon cloth for perfect aero, punctuated at distances from top to bottom either side as specified below.

The attention to detail on T6 is remarkable and the INEOS Britannia team are certainly adopting a measured, calm approach rooted in data and science. As a test-bed and data gathering tool to inform the design and engineering direction it’s the ultimate platform. We are not expecting to see T6 out on the water tomorrow and are awaiting an update to the recon schedule for later in the week.

Exciting times for the British. (Magnus Wheatley)

On-site observations c/o Justin Chisholm:

• Day 4 was a second day of mast setup and tuning which followed a similar procedure to Day 3.

• The boat was rolled out 0900 and positioned in the opposite orientation to day 3.

• The mast was rolled out 0915 while the boat was being chocked and tape measures attached before it was levelled up using hydraulic jacks.

• Between 1015 and 1025 the shore crew huddled in a briefing prior to stepping the mast.

• By 1035 the mast was on the crane and over the boat, and by 1055 the stays were all attached.

• A period of setup and testing using plumb lines, a laser and two theodolites took place prior to a lunch break at 1200.

• In the afternoon a ‘Backstay’ was fitted comprising of split lines with hydraulic ram located at the bottom.

• Hydraulic rams were also fitted to mid aft attachment points on either side that connected to the tracks at the aft ends of the decks.

• At around 1350 there was a loud noise like something releasing under load. On deck there was lots of attention paid to bow area aft of stem. After a period of investigation, the testing/setup procedure appeared to continue.

• De-rigging began at 1430 and by 1506 the mast was in the air the on crane.

• The mast touched down in its cradle at 1515.

• During the day a large steel frame structure was brought out of the main shed and positioned behind the base. It looked, perhaps, like a rig load test bed as it had a central ball mast step, a Harken Performa winch, and two lateral attachment points (all facing horizontally). This setup was not used during the day.

Observations on the mast:

Three square holes on either side covered with a square of material:

• 1 x 2 metres from top

• 1 x 2 feet above spreaders

• 1 x halfway between base and spreaders

• Twin mast tracks on outer edge of back face

• Twin hydraulic rams about a foot above mast base

Two holes on the aft face:

• 1 x just above spreaders (with halyards visible)

• 1 x in line with outer stay upper termination point.